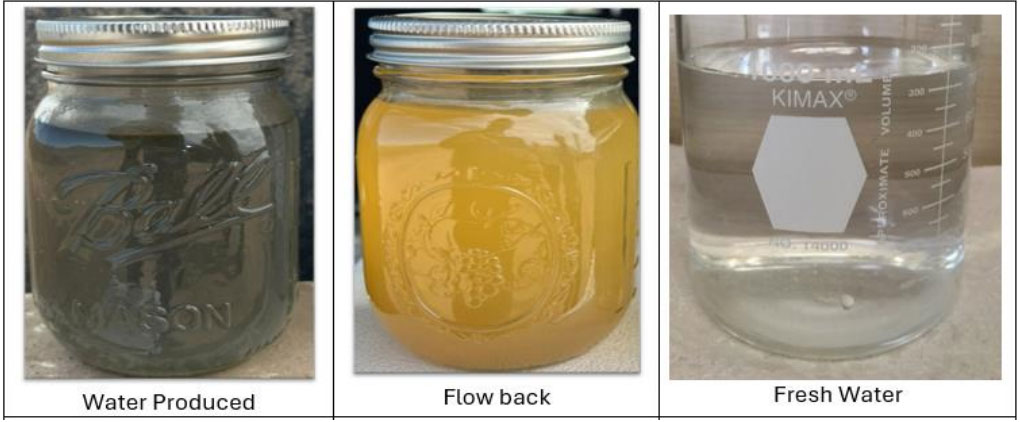

Water treatment in the Oil & Gas sector is a systematic process of unit operations that involve specific equipment and technologies that integrate operational flexibility to implement direct strategies to handle the different types of fluid such as production water, flow back and specific fluids for fracking work (fresh water), which are currently handled throughout both conventional and unconventional hydrocarbon production.

Every stage of extraction and production of hydrocarbons generates by-products which contain a series of physicochemical characteristics that make them unique and therefore their treatment is different. Let us start by understanding that production water is a mixture of hydrocarbons, dissolved salts, suspended solids, dissolved gases, and other contaminants that must be treated before disposal. On the other hand, flow back is the water that returns to the surface after hydraulic fracturing, which is loaded with high concentrations of suspended solids, dissolved solids, metals, natural contaminants of the formation and chemical additives used in the fracturing process. However, there are fluids that are required for various operations within fracturing processes, auxiliary processes (preparation of chemical products, etc.), and other activities inherent to the process of extraction and production of hydrocarbons such as fresh water.

It is crucial to determine the specific use of the by-products (production water, flow back, and fresh water) after treatment. The uses that can be given include injecting it back into the wells to maintain pressure, recycling water to mix it with fresh water and thus reduce total consumption and managing the fluid for its replacement and agro-industrial uses. These practices not only optimize water use, but also contribute to sustainability and operational efficiency, always ensuring compliance with environmental standards and regulations.

Transforming Water: Technology Solutions and Design Simulations

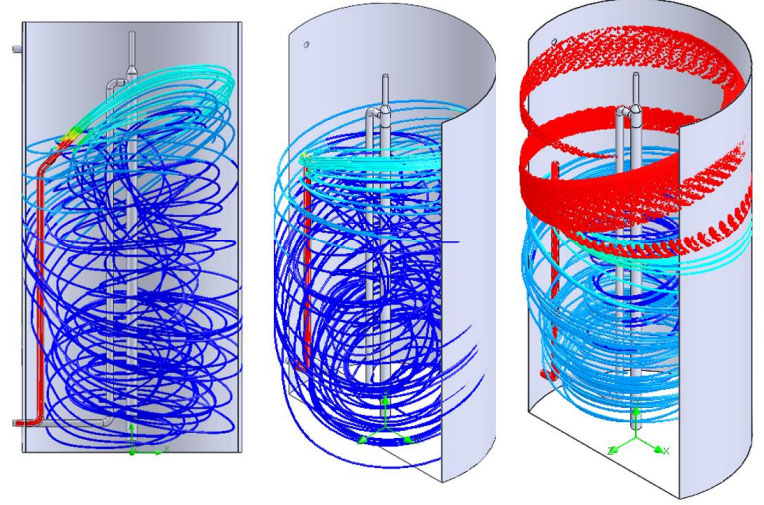

Simulation and the use of software are important tools to optimize the design and operation of treatment equipment. These simulations make it possible to predict the behavior of systems under different operating conditions, helping to identify improvements and mitigate possible operational risks.

The use of specialized software facilitates the integration of data and the performance of complex analyses, improving the precision and efficiency of the designs, considering process criteria and variables such as temperature, pressure, flow, vorticity, turbulence, velocity, etc.

In addition, the integration of process simulations in the laboratory integrates theory with real phenomena that cannot be predicted under a high degree of accuracy. This practice allows controlled tests to be carried out and real and reliable data to be obtained that can be used to land the simulations and improve the uncertainty of the operation of the equipment.

The combination of simulations and experimentation of the fluid in the laboratory provides a solid basis for the development of innovative and efficient solutions in water treatment, therefore, adopting technologies and processes based on mechanical, hydraulic, chemical and physical simulations in the laboratory will effectively allow the integration of the software with the development of the fluid in real conditions, which will allow the selection of technologies and customized designs according to the need.

Among the technologies and processes frequently used in water treatment are hydrocarbon separation technologies, whereas primary equipment can be found two-phase or three-phase separators (Free Water Knockout, FWKOS) where the crude and gas phase is directed to a primary separation system and the water phase is directed to dissolved air flotation (DAF) systems, which due to the effect of microbubbles are essential for the removal of free and emulsified hydrocarbons and also to increase the rate of ascent of colloidal particles, destabilized metals such as iron float for their subsequent removal from the process.

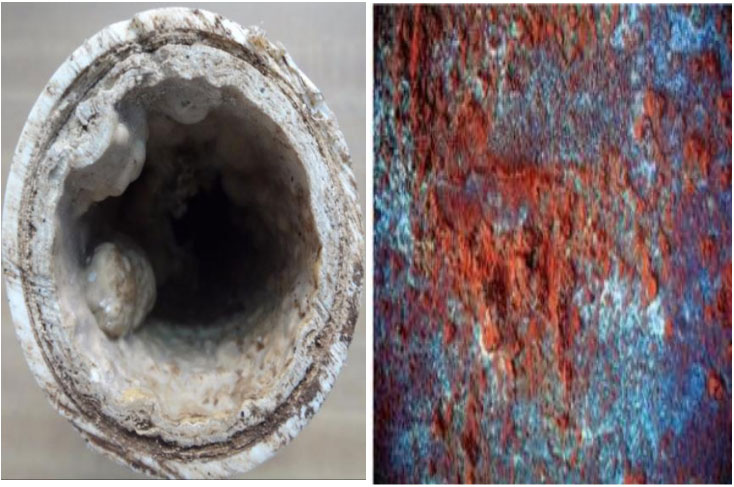

In another phase of the process, the use of selective filter beds for the removal and retention of metals at low pressure are technologies that provide operational flexibility and guarantee the treatments of contaminants such as TSS, particle size and turbidity, being highly effective in removing heavy metals from water, using adsorbent materials that capture and retain contaminants, thus allowing an efficient and low-cost treatment.

The technologies applied can vary according to the degree of demand and requirement at the end of the system, which is why technology such as nanofiltration is useful for the removal of sulfates and hardness from water, thus mitigating the formation of scale and controlling the acidity of the water, which is crucial to protect equipment and improve the efficiency of operations.

On the other hand, reverse osmosis is used to reduce the concentrations of ions, cations, and dissolved solids in the water, allowing the reuse of the water generated in the extraction process and generating various applications within the process.

As for advanced disinfection, they are processes capable of breaking down persistent organic compounds and microorganisms resistant to conventional treatments, leading them to a degree of bacterial inactivity (c ATPc < 10 pg/ml) respectively. Some of the precursors that achieve this degree of treatment are chlorine dioxide and ozone, which are highly oxidizing gases that are generated on site for greater performance.

Challenges in Water Treatment

Water treatment poses several challenges for the industry, among which it is identified that the different types of water present significant variations in their composition, which requires flexible and adaptable technologies. This variability can affect the efficiency of treatment processes and requires constant monitoring and real-time adjustments, in addition to this an important point is that these systems are transportable, modular, and dependable to guarantee such process variability.

Other aspects to consider are waste management, the reduction and safe disposal of by-products generated during treatment, such as sludge and brine, is an important aspect to consider from the beginning of the treatments and systems contemplated.

Therefore, the use of technologies that have the purpose of recirculating and reusing these previously treated fluids should be sought, promoting the recovery of water and liquid waste from the process.

On the other hand, energy consumption is a critical point, since many treatment technologies, especially those based on membranes, require more electrical power for their operation. The implementation of energy recovery systems and the use of renewable energy sources are key strategies that must be immersed in the conceptualization of the design and respective treatment, optimizing energy consumption is crucial to reducing the carbon footprint.

Sustainability, reuse and recycle of treated water are essential to conserve water resources and reduce dependence on freshwater sources, especially in hydraulic fracturing (fracking) processes. Evaluating fluid mixing alternatives such as production water with fresh water, or eventually replacing the use of fresh water with production water altogether not only saves but also reduces environmental impact.

Complying with environmental and water quality regulations, which vary between states, requires customized solutions and an innovative, straightforward approach. This means knowing local and national laws and implementing technologies and practices that ensure compliance with the strictest standards required by local and government entities.

Towards a more sustainable water management

Sustainability is a key aspect of water treatment in the Oil & Gas sector. Current practices focus on implementing advanced technologies and sustainable strategies to improve efficiency and reduce environmental impact. Technological innovation to address current and future challenges in water treatment will become a strategic ally to meet the current requirements of positive water management.

In conclusion, we can see that water treatment in the Oil & Gas sector faces numerous challenges, but also offers significant opportunities to improve sustainability and reduce the carbon footprint. The adoption of advanced technologies, the optimization of processes, the implementation of sustainable practices, the reengineering of existing equipment and the design of flexible systems are fundamental pillars to achieve high standards of efficiency, meet technical and environmental objectives, and move towards a circular economy.

At 1888 IS, we have been preparing to meet these challenges and support companies in the sector on their path to more efficient and sustainable water management. Our approach combines technological innovation, treatment system design expertise, and a strong commitment to sustainability. With solutions tailored to every challenge, we work to ensure cleaner processes, reduce environmental impact, and contribute to the achievement of global carbon footprint reduction goals.