It’s more crucial than ever to have a sustainable water treatment in the oil and gas industry, they are dependent on the best water quality for their operations, environmental regulations and business continuity.

The need for effective and sustainable treatment of water resources is becoming increasingly important for the energy sector, these companies rely on an adequate supply of water quality for better operations.

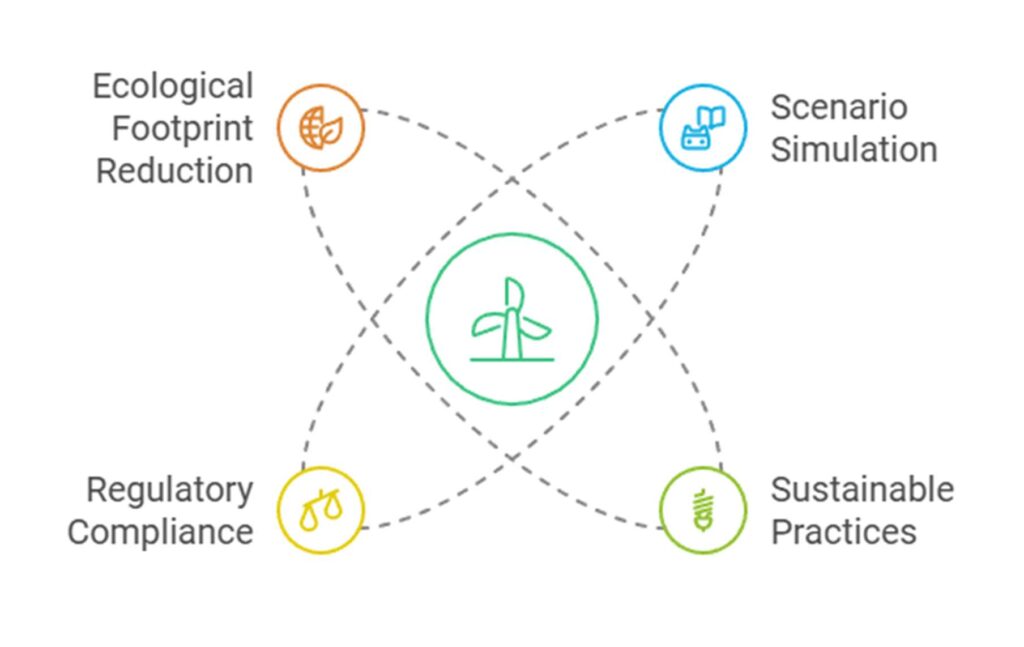

1888 Industrial Services is exploring the application of artificial intelligence (AI) to the optimization of produced water treatment in the oil and gas industry. Produced water establishes significant environmental challenges and operational costs as a byproduct of oil and gas production. Using AI technologies, 1888 IS can improve produced water treatment eƯiciency, reduce environmental impact and improve overall resource management.

Produced water, which contains a mixture of water, hydrocarbons, salts and various chemicals, is a waste stream produced during oil and gas separation. To minimize environmental risks and comply with regulatory standards, the treatment and disposal of produced water is critical also the produced water can be inefficient and expensive to manage using traditional methods, but by incorporating AI, these processes can be transformed, resulting in better decisions makings, preventive maintenance, and optimized treatment solutions.

AI Applications in Produced Water Treatment

- Predictive Analytics

AI can look at historical records to forecast volume, pressurization, flow rate, level, temperature and chemical composition of produced water. It’s with this predictive ability that operators can better allocate resources and lower operating costs by predicting treatment demand and tailoring treatment accordingly.

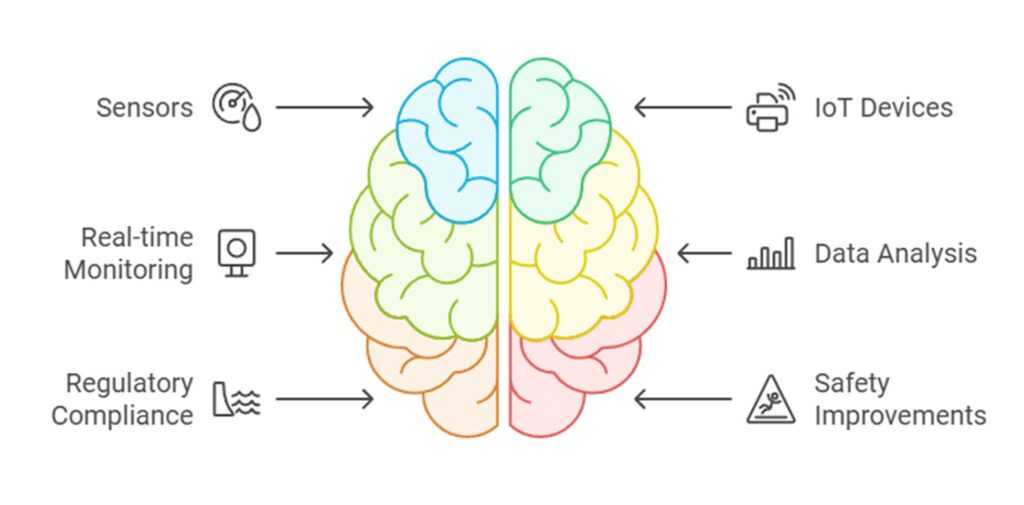

- Real-time Monitoring

Produced water quality and quantity can be continuously monitored using sensors and IoT devices. By providing real-time data, AI-powered technologies enable immediate response to changes in water characteristics. This ensures compliance with environmental regulations and improves safety.

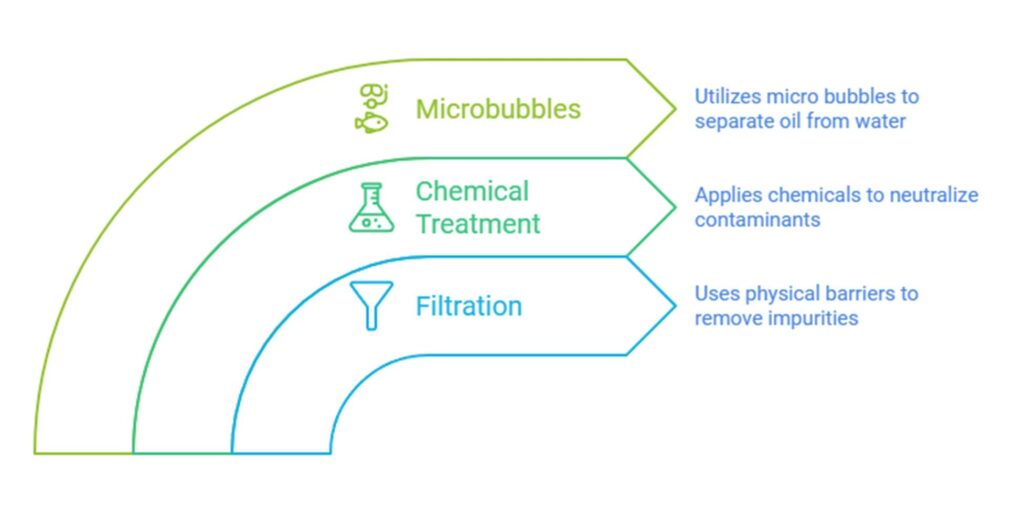

- Treatment Optimization

Machine Learning models can be used to make treatment as efficient as possible by comparing the different treatment strategies and how they work. In order to better recover water and reduce the amount of waste, AI can determine the optimal technologies combination for you — filtration, chemical treatment, DAF technology.

- Automated Decision-Making

Produced water management decisions can be automated with AI systems. By integrating data from multiple sources, AI can reduce the need for human intervention and speed response times by recommending the best course of action for treatment, disposal, or recycling.

Final Thought

The integration of artificial intelligence into water treatments solutions in the oil and gas sector presents a substantial opportunity to improve operational efficiency and environmental sustainability.1888 IS can help the Companies to improve their produced water management operations by using predictive analytics, real-time monitoring, treatment optimization and automated making decisions, As the O&G sector evolves, the use of AI technology will become increasingly important in addressing produced water concerns and guaranteeing a sustainable future.

1888 Industrial Services is developing the use of machine learning algorithms to improve PLC programming. A machine learning engine can evaluate data such as pressure and flow to identify patterns and optimize control parameters. Historical data can also be used to improve control strategy and predict future outcomes.