Author: Monica Martinez – Chemical

Engineer – 1888 IS

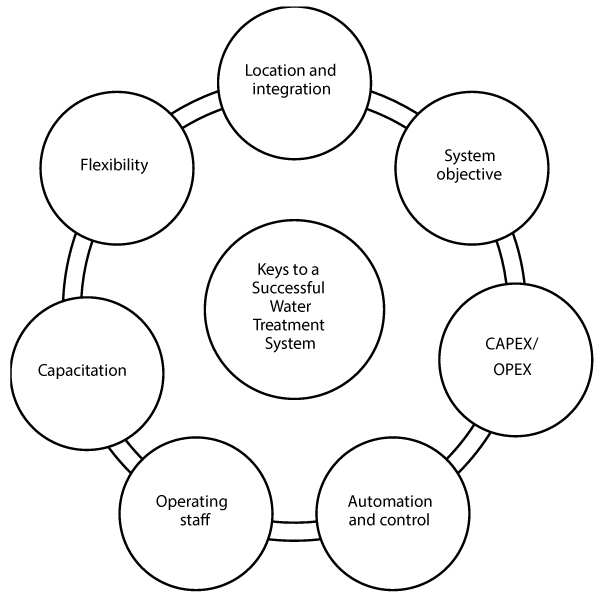

A significant portion of water treatment systems end up being abandoned. Why? Designing a water treatment plant is not only about meeting regulatory requirements, it must also be conceived as an integral system, meaning it should be viable, operable, and sustainable over time.

Among the main causes of system abandonment are high operating costs, excessive system complexity during operation, unskilled operating personnel, lack of flexibility to handle variations in flow or water quality, among others. To avoid these issues, several key factors must be considered during the design stage of the treatment system.

Geographic location: Location makes all the difference. Availability of energy and water, transportation and access routes, site security, climate conditions, available space, and other aspects can either facilitate or hinder the operation and maintenance of the system.

System objective: The selection of the appropriate treatment technology largely depends on the intended purpose of the system: regulated discharge, specific industrial use, internal reuse, among others. Since different technologies can achieve

similar results, the key is not only the process itself, but also its suitability for the environment and the end user.

treatment system. Source: Own work

CAPEX/OPEX: CAPEX refers to the initial investment in equipment and installation, while OPEX refers to the

operating and maintenance costs of the system over time. This economic factor determines long-term sustainability. A system that is cheap to install but expensive to operate usually fails; conversely, one that balances investment with operating costs endures over the years.

Automation and control: This factor is essential to ensure proper system performance. While high automation does not guarantee success, a 100% manual system is not ideal either, as it is prone to human error and inefficiency. The goal is to find a balance aligned with both the budget and the end-user’s capabilities. However, it is important to highlight that once automation is introduced, specialized technical support is required within operation and maintenance to address the system’s long-term needs.

Human factor: The best technology will fail without competent human resources behind it. Knowledge transfer to the personnel responsible for system operation and maintenance is critical. Operators must not only understand the system but also be capable of making decisions when needed. For this, it is essential that the workforce develops ownership and

accountability for the system, something that should begin as early as pre-commissioning and commissioning stages, allowing staff to strengthen their knowledge and build a sense of responsibility toward each unit and stage of the process.

In addition, it is necessary to foster a culture of continuous training for operating personnel, both to reinforce knowledge and to receive feedback from real operational scenarios. This practice enables adjustments and process improvements that enhance system efficiency.

System flexibility: From the first day of design and engineering until the day the system begins operating, weeks, months, or even years may pass depending on the project. For this reason, design must consider potential changes, such as increased production flows, variations in water quality, or new regulatory requirements. A robust system must be prepared to grow

and/or adapt over time.

Finally, a well-structured treatment system can also generate added-value opportunities. Some process by products can be reused internally or externally, providing additional revenue streams or cost savings in other areas of the company. This potential can be identified during design or later in operation, turning the system into an even greater source of benefits.

The real success of a water treatment system does not lie in getting it up and running for the first time, but in seeing it operate efficiently 5, 10, or even 20 years later. When design engineering is combined with a realistic budget, trained personnel, clear objectives, an adequate location, and an appropriate and flexible level of automation, the plant ceases to be an expense and becomes a strategic asset for both the company and the environment.

At 1888 IS, we understand that the success of a water treatment system does not depend solely on the installed technology, but on integrating all these factors into a coherent and sustainable solution.

Our team has the experience and technical capabilities to design, implement, and support the operation of various types of water treatment systems, ensuring that each project adapts to the specific needs of the industry. Thanks to this comprehensive approach, we deliver systems that not only work from day one but remain a long-term strategic asset.